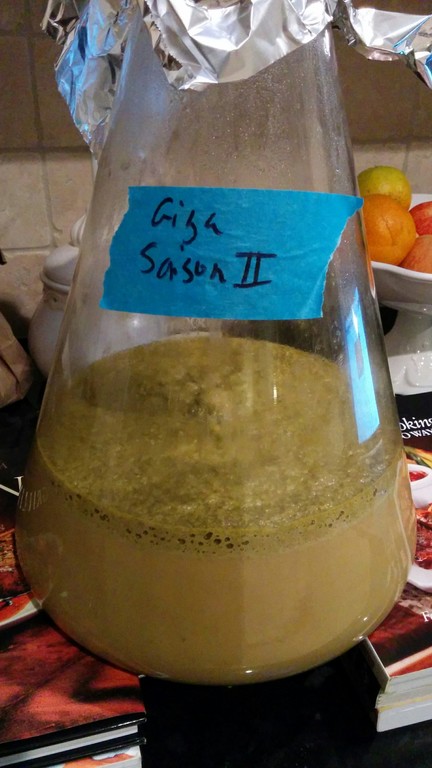

Barleywine Primary Fermentation with Wyeast 1388

When I first started brewing beer it only took 4 or 5 sessions before I was ready to attempt a really big beer. I had been discussing what sort of beer to brew with my brother-in-law and he suggested we brew something big that we could do yearly. We settled on a barleywine, english varient so it wasn’t too hoppy. We’d brew this beer and then age it for a year and crack it open when we brewed it the next year.

In planning for this big beer we also decided that we should run a partigyle session since we’d have so much extra sugar for a big beer. With a recipe in place for both beers, we set out to do an all-grain, brew-in-a-bag, 5 gallons of 1.115 S.G wort and 5 gallons of about 1.040 third-runnings which would be boosted with some Amber Liquid Malt Extract (LME).

On the big day we doughed in as much grain as would fit in the 15.5 gallons keggle we had. After 75 minutes and some seriously heavy lifting of the bag out of the pot we had our 7.5 gallons of wort; only it was massively short on gravity for our 1.115 beer. We had a decision to make… have a less-than-big barleywine and a solid pale or fix the big guy. We decided to ensure the big beer came out big. All 6 pounds of LME when in, along with a couple pounds of sugar. The other slight miscalculation was the hop bill. I had completely forgotten the hops, which were English, Fuggle and Northdown IIRC from the original recipe. We substituted some American hops, whatever we had on hand, Chinook and Cascade. The rest of the brew day went fine. The barleywine fermented out cleaning, tasting of hot booze with some orange in there, sort of like Grand Marnier, which wasn’t a bad place to be. We racked the beer into a 5 gallon corny keg and put it in the closet for a year.

This beer would turn into something spectacular… and I’ve been asked to brew this again many times, but since the time that I brewed this beer my palate has changed enough that I cringe thinking about 5 gallons of barleywine. Young, I can handle a bottle or two, but the aged variety end up being far too malty for me. With pledges of support for drinking the result, and an opening in the 5 gallon whiskey barrel pipeline; I decided that we’d rebrew this recipe, updating it a bit and get to use the proper ingredients. This beer won’t be the same as the original, but hopefully it will be come just as good. First aging in the whiskey barrel for a few months and then beyond that in bottles.

Recipe Details

| Batch Size |

Boil Time |

IBU |

SRM |

Est. OG |

Est. FG |

ABV |

| 6 gal |

90 min |

116.7 IBUs |

19.3 SRM |

1.099 SG |

1.023 SG |

10.1 % |

Style Details

| Name |

Cat. |

OG Range |

FG Range |

IBU |

SRM |

Carb |

ABV |

| English Barleywine |

19 B |

1.08 - 1.125 |

1.018 - 1.03 |

35 - 70 |

8 - 22 |

1.6 - 2.5 |

8 - 12 % |

Fermentables

| Name |

Amount |

% |

| Pale Moon (Blacklands) |

18 lbs |

80 |

| Munich Malt |

1 lbs |

4.44 |

| Victory Malt |

1 lbs |

4.44 |

| Crystal, Medium (Simpsons) |

0.5 lbs |

2.22 |

| Pale Chocolate (Crisp) |

0.5 lbs |

2.22 |

| Special B Malt |

0.25 lbs |

1.11 |

| Sugar, Table (Sucrose) |

1.25 lbs |

5.56 |

Hops

| Name |

Amount |

Time |

Use |

Form |

Alpha % |

| Magnum |

1.69 oz |

60 min |

Boil |

Pellet |

14 |

| Comet |

2 oz |

25 min |

Boil |

Pellet |

8.6 |

| Comet |

1 oz |

5 min |

Aroma |

Pellet |

8.6 |

| Fuggles |

3 oz |

14 days |

Dry Hop |

Pellet |

4.5 |

Miscs

| Name |

Amount |

Time |

Use |

Type |

| Calcium Chloride |

3.70 g |

60 min |

Mash |

Water Agent |

| Gypsum (Calcium Sulfate) |

3.50 g |

60 min |

Mash |

Water Agent |

| Epsom Salt (MgSO4) |

0.70 g |

60 min |

Mash |

Water Agent |

| Whirlfloc Tablet |

1.00 Items |

15 min |

Boil |

Fining |

| Coriander Seed |

0.75 oz |

10 min |

Boil |

Spice |

| Orange Peel, Bitter |

0.75 oz |

10 min |

Boil |

Spice |

| Orange Peel, Sweet |

0.75 oz |

10 min |

Boil |

Spice |

| Yeast Nutrient |

1.00 tsp |

5 min |

Boil |

Other |

Yeast

| Name |

Lab |

Attenuation |

Temperature |

| Belgian Strong Ale (1388) |

Wyeast Labs |

75% |

65°F - 75°F |

Notes

Mash:

Keep Roast Grains till end of mash:

Pale Chocolate (8 oz)

Special B (4 oz)

|