I can’t quite remember when but this hoppy pilsner, Real Ales’ Hans’ Pils somehow took over as my go-to beer on any night of the week. It has a mild malt sweetness tempered with a heavy dose of an herbal Nobel hop, Tettnanger. The rush of hops over the malt, peaking and then slowly fading for a long, dry finish is just fantastic. And here is the clencher; it’s so reasonably priced that it is now my benchmark. If I can get a 12-pack for a little over $1 a can; why would I pay double or triple that unless the beer is offering something new.

I’m not interested in replacing Hans Pils in my fridge; I’m pretty sure Real Ale is just going to keep knocking this one out consistently and I want to do my part to keep it coming, however I am interested in if some of my newer equipment and process won’t help me get pretty close to an excellent pilsner. To that end, I’ve pulled in a few new things for me. I’m giving the Brülosophy’s lager fermentation schedule a try.

I always use a yeast starter, so that part isn’t new. But for this lager, I decided that I’d boost the pitch rate significantly. My favorite starter tool is over at Brewer’s Friend. I selected the Pro-brewer lager rate, or 1.75 million cells per mL per degrees plato. What that meant was a two steps of 5L each, using 1lb of Dry Malt Extract each go. I hope that the extra effort to increase the amount of yeast when pitching will result in a super clean yeast profile.

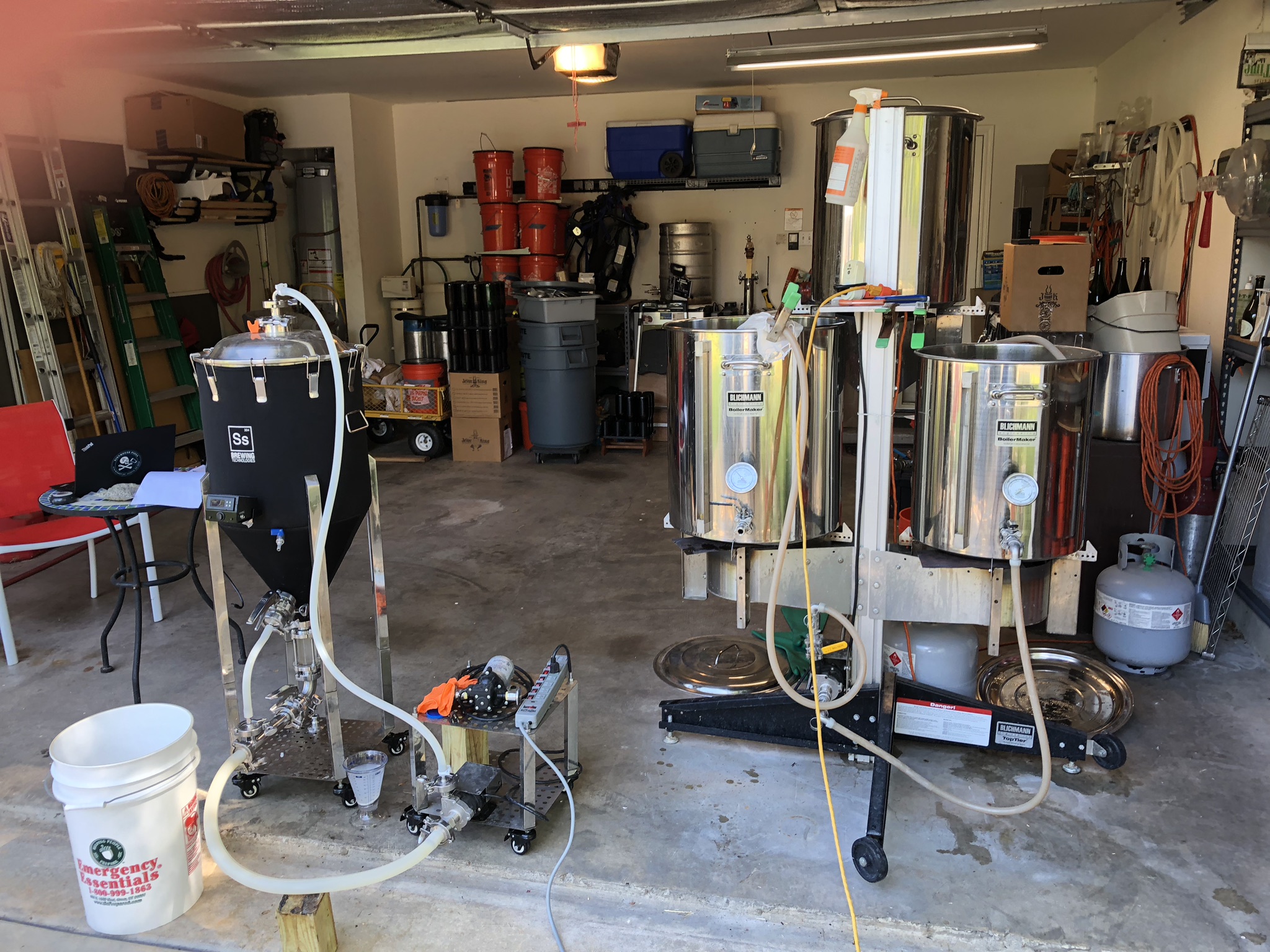

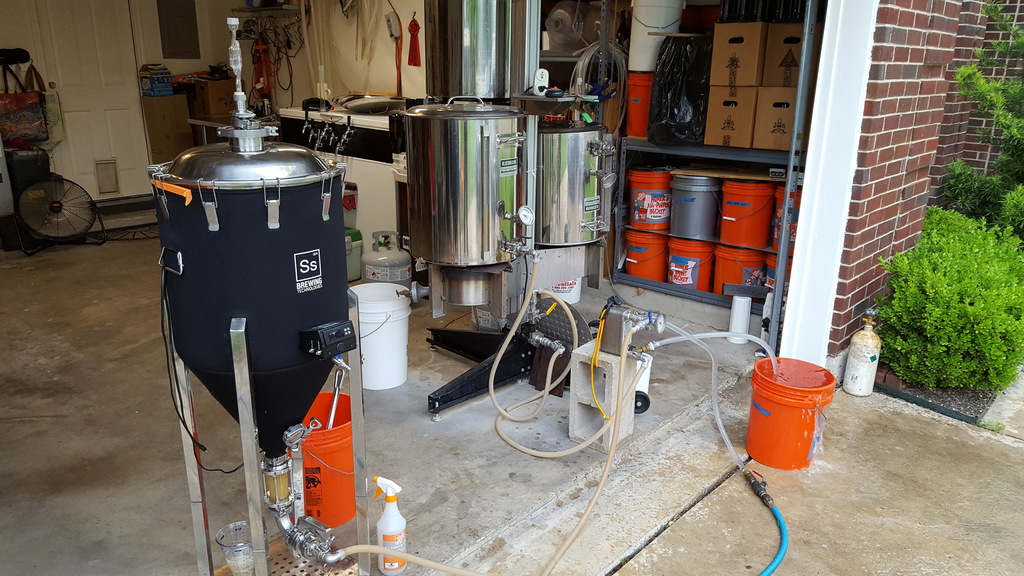

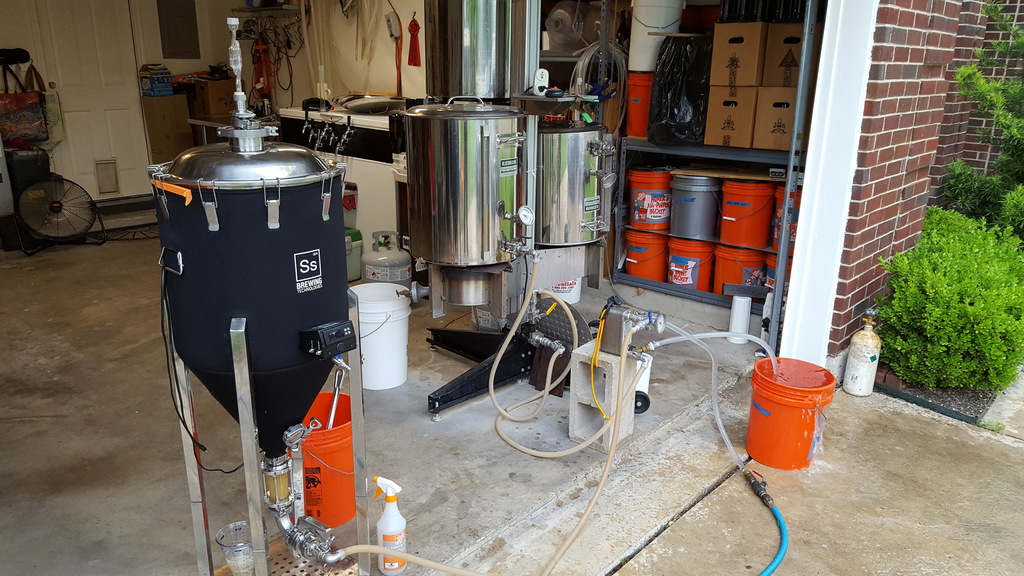

Here’s a walk through some of the brew day today.

After an uneventful 75 minute mash at 148F, I’m sparging with 180F water into the mash tun; I had already recirculated the mash to raise the temp to 168F to stop conversion. When I lauter, I usually go fairly fast; I’ve never really wanted to wait that long and my efficiency hasn’t been so low that I’m looking for ways to increase things.

All pilsner malt comes into the boil kettle looking just perfect.

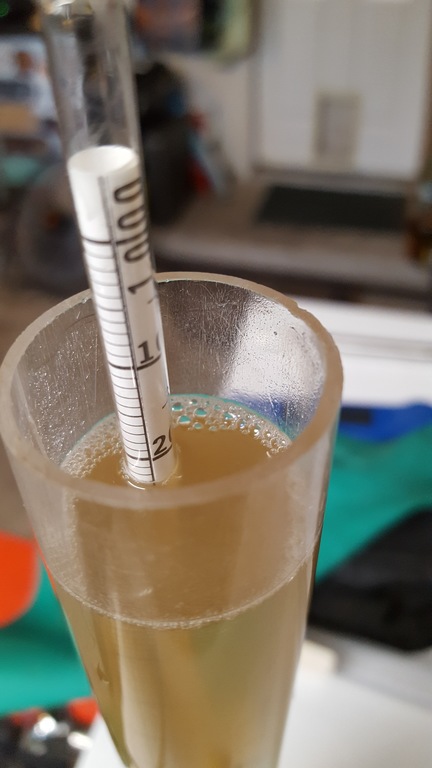

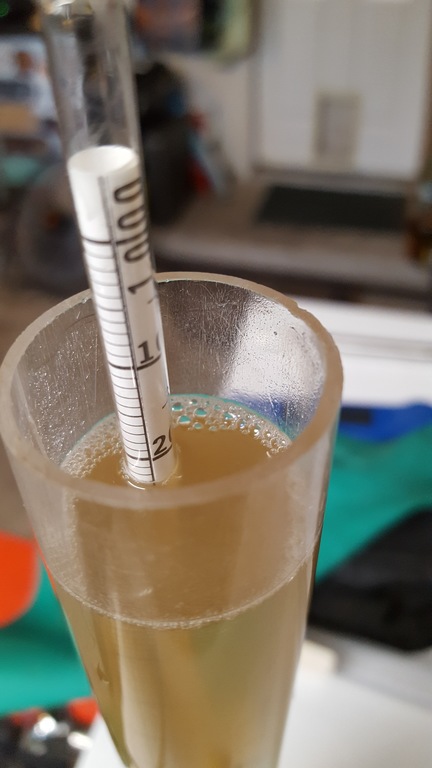

I measure pre-boil gravity, usually with both a refractometer and my hydrometer for comparison. Today the hydrometer showed 1.047 S.G and the refractometer had 1.049 S.G. Good enough for me.

One other change for me was to skip the use of my silicone-based anti-foamer both in the yeast starters as well as the boil. I’m seeing if this has a meaniful effect of head retention once the beer is finished. That meant I did have to wrangle the hot break at the start of the boil when I normally don’t even have to look once.

My favorite part of switching to a conical with glycol chiller is no longer having to recirculate ice water to get fermentation temperature. I just use ground water which gets me to 80F and then connect and start the glycol loop to bring it down to the target temperature. In this case, I’m pitching at 48F.

I’m really excited to see how this one comes together. Here’s my take on my favorite hoppy pils, Hans Pils:

Recipe Details

| Batch Size |

Boil Time |

IBU |

SRM |

Est. OG |

Est. FG |

ABV |

| 15 gal |

90 min |

44.3 IBUs |

3.4 SRM |

1.050 |

1.009 |

5.4 % |

|

Actuals |

1.055 |

0 |

0.0 % |

Style Details

| Name |

Cat. |

OG Range |

FG Range |

IBU |

SRM |

Carb |

ABV |

| German Pilsner |

3 2 |

1.044 - 1.05 |

1.008 - 1.013 |

25 - 45 |

2 - 5 |

2.4 - 2.6 |

4.4 - 5.2 % |

Fermentables

| Name |

Amount |

% |

| Pilsen (BestMälz) |

29 lbs |

100 |

Hops

| Name |

Amount |

Time |

Use |

Form |

Alpha % |

| Magnum |

1 oz |

60 min |

Boil |

Pellet |

14.1 |

| Tettnang |

6 oz |

30 min |

Boil |

Pellet |

3.7 |

| Tettnang |

4 oz |

5 min |

Boil |

Pellet |

3.7 |

Miscs

| Name |

Amount |

Time |

Use |

Type |

| Phosphoric Acid 20% |

33.60 ml |

60 min |

Mash |

Water Agent |

| Epsom Salt (MgSO4) |

3.00 g |

60 min |

Mash |

Water Agent |

| Gypsum (Calcium Sulfate) |

0.70 g |

60 min |

Mash |

Water Agent |

Yeast

| Name |

Lab |

Attenuation |

Temperature |

| Copenhagen Lager (WLP850) |

White Labs |

75% |

50°F - 57.2°F |

Mash

| Step |

Temperature |

Time |

| Saccharification |

148°F |

75 min |

| Mash Out |

168°F |

10 min |