Two-story Nor’Easter IPA — looking quite hazy!

Has it really been almost six months since the last brew? Yes. Yes it has. It turns out that life, including moving your house does happen to take up precious brewing time. We moved, not far, in April and it was a crazy time with getting the old house in order, buying a new house, selling the old and figuring out what to do with all of the things… (#kondotime).

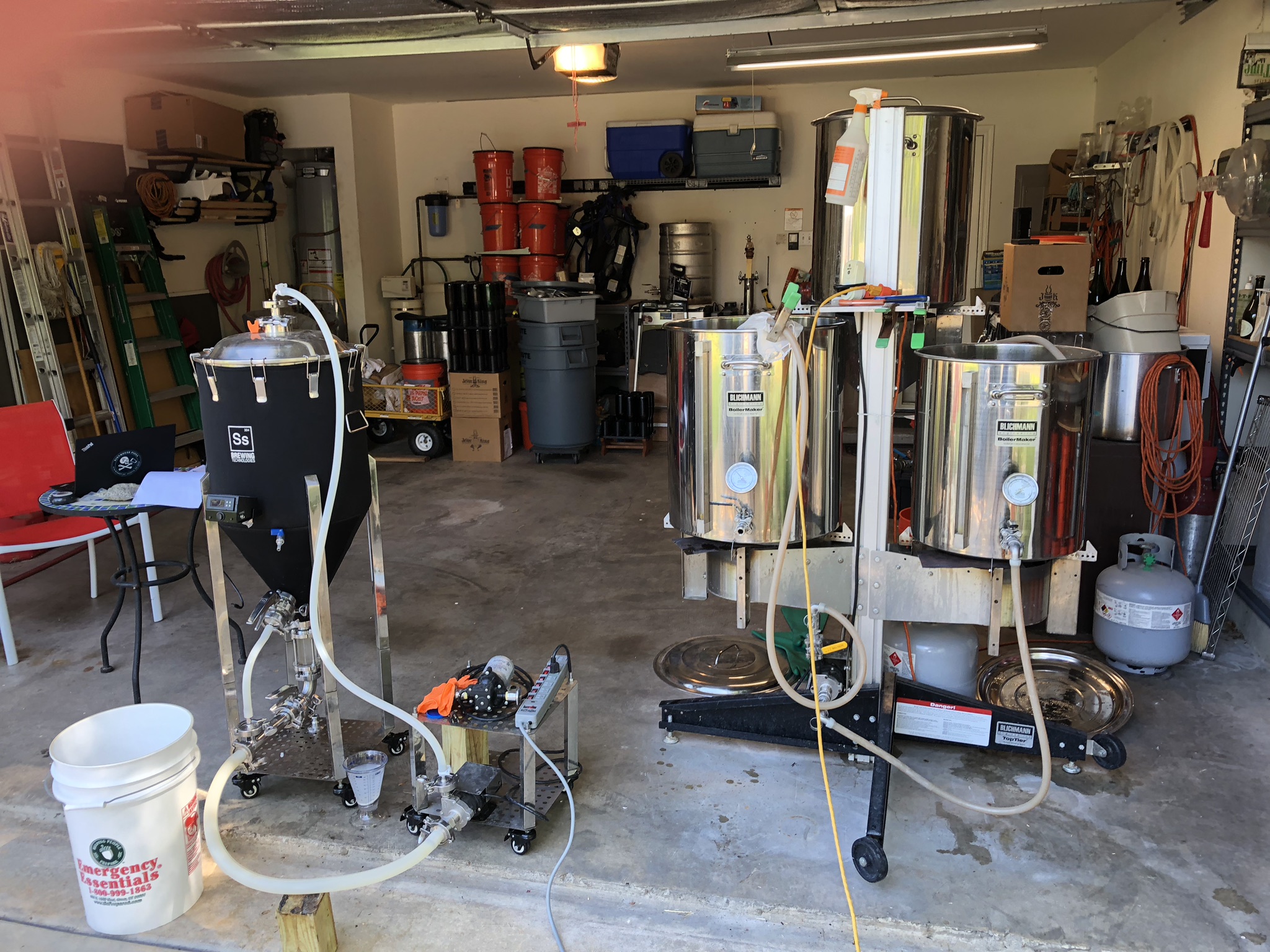

New garage/brewery layout. I used some of the shelves from the shed and I’m looking forward to using hooks and a pulley to add/remove kegs from keezer.

It does bring a small tear to my eye that I no longer have a BattleShed, as it was affectionately called for some time. Good friends of mine worked many hours to help insulate and prepare the shed to perform as a beer cellar. There were many ups and downs with the shed. I won’t forget the first time I tried to roll at 15 Gallon barrel up into the shed; I eventually got it in there. I also remember walking out in the morning and hearing the AC unit “announce” that it had frozen the coils again. After nearly 4 years of shed-life, one thorough cleaning of the AC unit to restore full functionality and a quarter of the floor being destroyed due to water leakage from a said AC unit it was time to say goodbye.

Brewbucket water leak test. Definitely needed. Had to swap where o-rings were and check fittings.

With the shed gone and new new replacement it did mean some hard decisions on future brewing. Upgrading to the half-barrel Chronical was a massive improvement in beer quality (not to mention quantity). However, during experimentation phase, it did punish the budget (NEIPAs are super pricey when making 15 gallon batches), and mean that even successful batches didn’t get completely consumed soon enough to avoid going bad. So, I’m transitioning back to five or six gallon batches. I picked up a SS Brewtech Brewbucket with the cooling attachments which work perfectly with the existing glycol chiller loop I have. And later this summer I’ll also switch to electric brewing; looking forward to the easier mash temp control. More on that later.

Brewstand still holding up. Put the 30G up for the HLT and moved the 20G back to boil kettle.

What to brew for a first batch then? I had stepped away from NEIPAs while I worked out more details on recipes, techniques, malt bills, pH, hop creep, yeast strains; the whole nine yards. I’m a huge fan of Scott Janish’s blog which explored so many aspects of NEIPAs that I found to be critical to producing a really excellent beer of the style. The recent recipe from Scott caught my eye and I decided to start there. The other area of interest that I’ve been chasing down was a local brew pub (Pint House Pizza) which makes some really top-notch NEIPAs in our area has mentioned in several interviews that their house strain is not as affected by diacetyl and hop-creep as other well known strains. Joe Morhfield of PHP is very open about recipes and providing feedback to homebrewers; but on this point they keep their house strain to themselves. I don’t know definitively but I’m making an educated guess and for this batch I picked up White Labs German Ale yeast (WLP 029). I’ve seen several threads about a “fruity” ale yeast which finishes fairly dry.

Let’s see how this one comes out. The recipe follows after some brewday pics!

Enjoy!

Milky Oatmeal with that Flaked Barley

Where was my larger nylon bag? #IHateMoving

Fly sparge!

Transfers are really simple with gravity and no poppet valves.

Co2 Blanket added to source and destination

Recipe Details

| Batch Size |

Boil Time |

IBU |

SRM |

Est. OG |

Est. FG |

ABV |

| 6 gal |

60 min |

62.8 IBUs |

4.0 SRM |

1.061 |

1.018 |

5.6 % |

|

Actuals |

1.05 |

1.012 |

5.0 % |

Style Details

| Name |

Cat. |

OG Range |

FG Range |

IBU |

SRM |

Carb |

ABV |

| American IPA |

13 2 |

1.056 - 1.075 |

1.01 - 1.018 |

40 - 70 |

6 - 15 |

2 - 2.8 |

5.5 - 7.5 % |

Fermentables

| Name |

Amount |

% |

| Brewers Malt 2-Row (Briess) |

7 lbs |

51.85 |

| Barley, Flaked |

3 lbs |

22.22 |

| Wheat - Red Malt (Briess) |

3 lbs |

22.22 |

| Acidulated (BestMälz) |

8 oz |

3.7 |

Hops

| Name |

Amount |

Time |

Use |

Form |

Alpha % |

| Columbus (Tomahawk) |

0.35 oz |

30 min |

Boil |

Pellet |

14 |

| Cascade |

1.98 oz |

30 min |

Aroma |

Pellet |

5.5 |

| Citra |

1.98 oz |

15 min |

Aroma |

Pellet |

12 |

| Columbus (Tomahawk) |

1.76 oz |

15 min |

Aroma |

Pellet |

14 |

| Citra |

0.99 oz |

14 days |

Dry Hop |

Pellet |

12 |

| Galaxy |

0.99 oz |

14 days |

Dry Hop |

Pellet |

14 |

| Huell Melon |

1.98 oz |

2 days |

Dry Hop |

Pellet |

7.2 |

Miscs

| Name |

Amount |

Time |

Use |

Type |

| Calcium Chloride |

5.60 g |

60 min |

Mash |

Water Agent |

| Gypsum (Calcium Sulfate) |

2.40 g |

60 min |

Mash |

Water Agent |

| Lactic Acid |

1.20 ml |

60 min |

Mash |

Water Agent |

Yeast

| Name |

Lab |

Attenuation |

Temperature |

| German Ale/Kolsch (WLP029) |

White Labs |

75% |

65°F - 69°F |

Mash

| Step |

Temperature |

Time |

| Saccharification |

157°F |

35 min |

| Mash Out |

168°F |

15 min |

Notes

Calcium Cloride @ 1g / Gal. , Gypsum @ 0.5g / Gal

Huell Melon @ 2nd day

All the rest @ 7th day

https://scottjanish.com/headspace-hazy-ipa-oxidation/

Mash pH was a bit lower than anticipated, resulting in 10 point

gravity loss. Partly due to adding 2.5mL of Phosphoric Acid

rather than the 1.2mL as listed. However, the resulting beer is

quite excellent so not a terrible issue. Maybe lowering efficiency

numbers and adding a pound or two of malt to adjust.

Hop combo isn't my favorite; I like a bit more grapefruit. Next time

I'd toss Azacca and some El Dorado or Eukonaut in place of H. Melon.

Would also entertain some Simcoe for an orange direction as well.

Galaxy was sorely missed but out of stock. |