Homebrew Mosaic IPA on the left, Yellow Rose on the right.

Brewing and IPA just the way you want has always proved to be more difficult that I’ve wanted. The Mosaic IPA is no different. I’ve had plenty of Lone Pint’s Yellow IPA to know what I really liked about it: huge amazing Mosaic nose and aromatics, sweet, but light malt flavors, and a solid bitter and dry finish.

V1 was a small batch and didn’t quite attenuate exactly as intended, partly due to learning temps and mashing in the small batch setup but it was in the ballpark for what we wanted in a clone.

V2 was a scaled up to a 6 gallon batch. When I brewed V2 I did have a slight shortage of Mosaic hops and had to go with a Mosaic/Simcoe blend. In tasting, this had almost zero impact in aroma and flavor. That wasn’t too surprising considering Mosaic’s heritage. Color was spot on as well as clarity. The real difference was in the taste. In a side-by-side with a bottle of Yellow Rose, it was clear that my V2 was sweeter than YR; something I knew as I was sampling V2. V2 finished around 1.016 or so which is much sweeter than my palate enjoys nowadays. However, beyond the sweeter malt flavors it was lacking some of the hop bite.

The reviews of V2 were all similar: good, but not quite right, needs more hops. Well, that’s not a problem. So on to V3! I wanted to achieve two things. First, and foremost, the beer needed to finish drier than V2. Considering the yeast I have, Dry English Ale, which already does a really solid 75 to 80% attenuation, I decided I’d employ some step mashing to maximize beta amylase hoping to reduce the final gravity. The second goal was to bump up the bitter a bit as well, oh and this time use all Mosaic for sure.

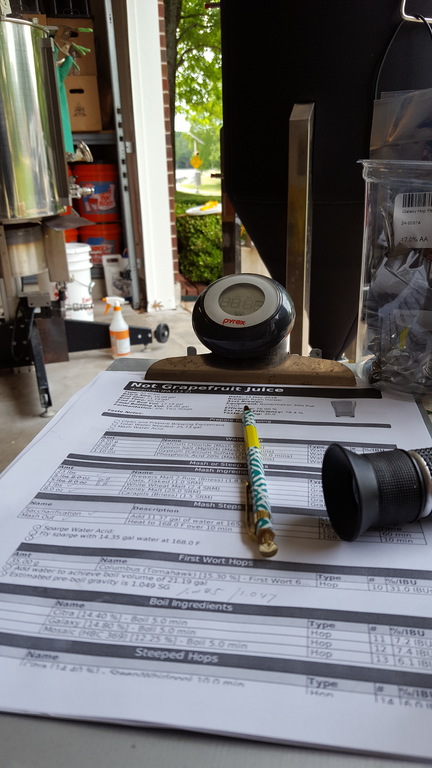

The recipe below includes these changes. Brewing of V3 was picture perfect. However, somewhere along the mash, we accidentally bumped the efficiency from 72% to around 93%. The pre-boil gravity target was to be 1.045 and we ended up with 1.055. The final O.G ended at 1.083 instead of 1.067 meaning we had a 9% beer bordering on double IPA rather than a solid 6.5% IPA. Worse things have happened.

Upon tasting V3 though it wasn’t significantly more bitter than V2 and it immediately dawned on me that the additional efficiency was the source of the trouble. Since the boil gravity was much higher than expected, that resulted in a lower alpha-acid isomerization, and lower IBUs in the final product. I should have adjusted the amount of hops in the boil to combat the higher gravity wort. Clearly a V4 will be needed.

V3 finished at 1.016, but considering the starting gravity I don’t think I can expect WLP 007 and mash techniques to get any lower. 80% attenuation is the top end for this ale strain. But I know some other strains that can go a bit higher. For V4, I’ll brew another 6 gallons of wort but this time pitch my favorite strain, the Jester King mixed culture.

The Jester King blend attenuates just about anything down to 1.000 SG. Jester King already produces a number of highly hopped beers, namely Wytchmaker Rye IPA and El Cedro, Cedar IPA. I’m also interested in their collaborations with many breweries in which they use wort produced by their partners and then pitch the mixed culture and see what sort of beer it becomes.

V4 will use the same recipe as V3, but will use the JK mixed culture instead. Fermentation temperature will change as well, the JK blend tends to produce a more sour wort at cooler temperatures, so a minimum temp of about 75F or higher will be used to encourage the yeast to dominate and keep the bacteria in check (at least for a while). As a bonus, cold conditioning in bottle will keep hop aroma as the brett is an oxygen consumer and the bacteria like to produce some lactic acid! Who doesn’t want a hoppy sour beer? =)

Recipe Details

| Batch Size |

Boil Time |

IBU |

SRM |

Est. OG |

Est. FG |

ABV |

| 6 gal |

90 min |

81.0 IBUs |

4.1 SRM |

1.066 |

1.015 |

6.7 % |

|

Actuals |

0 |

1.01 |

-75.8 % |

Style Details

| Name |

Cat. |

OG Range |

FG Range |

IBU |

SRM |

Carb |

ABV |

| American IPA |

14 B |

1.056 - 1.075 |

1.01 - 1.018 |

40 - 70 |

6 - 15 |

2.2 - 2.7 |

5.5 - 7.5 % |

Fermentables

| Name |

Amount |

% |

| Pilsen (BestMälz) |

14.764 lbs |

100 |

Hops

| Name |

Amount |

Time |

Use |

Form |

Alpha % |

| Mosaic |

0.99 oz |

90 min |

Boil |

Pellet |

11.6 |

| Mosaic |

1.62 oz |

10 min |

Boil |

Pellet |

11.6 |

| Mosaic |

1.62 oz |

20 min |

Aroma |

Pellet |

11.6 |

| Mosaic |

3.17 oz |

5 days |

Dry Hop |

Pellet |

11.6 |

Miscs

| Name |

Amount |

Time |

Use |

Type |

| Gypsum (Calcium Sulfate) |

4.60 g |

60 min |

Mash |

Water Agent |

| Calcium Chloride |

2.70 g |

60 min |

Mash |

Water Agent |

| Epsom Salt (MgSO4) |

1.90 g |

60 min |

Mash |

Water Agent |

| Whirlfloc Tablet |

1.00 Items |

15 min |

Boil |

Fining |

Yeast

| Name |

Lab |

Attenuation |

Temperature |

| Dry English Ale (WLP007) |

White Labs |

75% |

65°F - 70°F |

Mash

| Step |

Temperature |

Time |

| Beta Rest |

140°F |

45 min |

| Saccharification |

152°F |

20 min |

| Mash Out |

168°F |

10 min |

Notes

Beta Focus for dryer beer:

Mash in 140F, hold 40 mins

Raise to 152, hold for 20 mins |