It’s Texas winter time again; well sort of. Texas has the strangest winters; it was 85F on December 25th, and then had a high of 28F for 3 days in early January. Today is 72F. Despite these wild swings in temperatures, it’s time again to brew my annual Lambic-style, or Methode Gueuze, as the newly introduced mark for a process has been released alongside a huge accomplishment from Jester King when they released SPON late last year. Note, I won’t be performing a turbid mash. Yet.

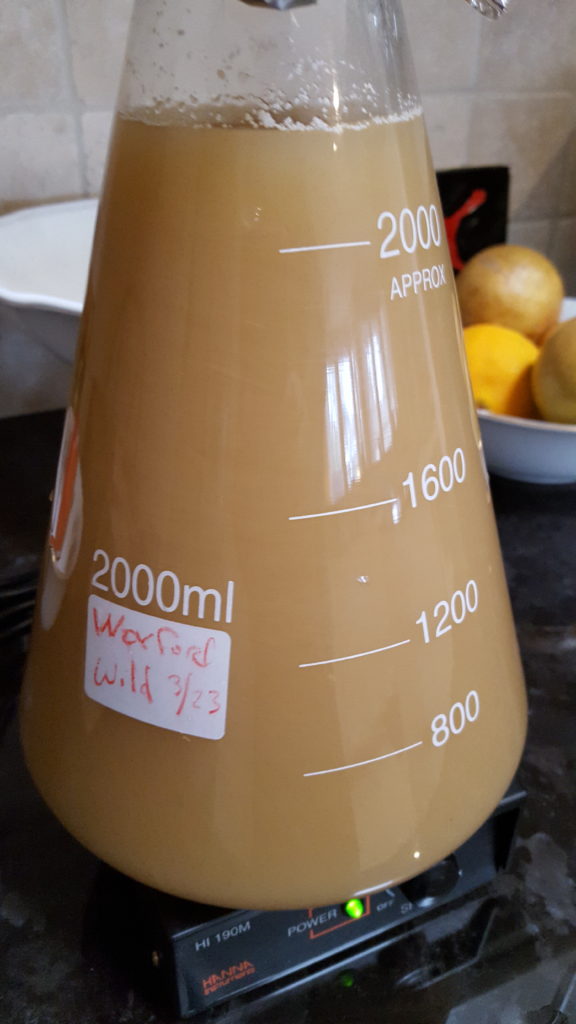

In preparation for my first year of blending, I’m doing my largest single batch. 22 Gallons of wort to be split between a 15 gallon Rye Whiskey barrel, and a 5 gallon Whiskey barrel. The 15 gallon barrel will get a fresh pitch of ECY 20, my favorite blend for long barrel aging lambic-style beers. The 5 gallon will get wild yeast I captured under a peach tree from my yard. I brewed a 1L starter a year ago which produced Belgian-like characteristics by not much in the way of sour. After aging for nearly 9 months, the pH dropped from 4.2 to 2.8. Slow bugs work magic. I just refreshed this mixed culture to pitch into the 5 gallon barrel to see how that turns out.

These two barrels are the newest in my collection and need to be parafin waxed. Using Gulf wax in a glass bowl, heat gun set at 1000F and a thermal glove one can drip and blend hot wax on the whole barrel (outside and both heads) in about 20 to 30 minutes. I’ve done this for all 3 of my Woxbic barrels and it’s done amazingly well at keeping any acetic character out of even the 3 year old beer which has been stored at approx 75F for the entire time.

After this brewday, the next big challenge is blending the 3, 2 and 1 year old blends, and then how to plan for next years’ blends. I find it incredibly difficult to determine how to keep a consistent amount of 3, 2 and 1 year old lambic beer around considering the blending ratios may change. One can always brew more each year but it becomes challenge to use up the remaining beer that’s beyond the 3 year mark. I plan to take what I need out of the 3 year old barrel and anything that remains will get bottled as straight unblended lambic-style; sort of a Grand Cru or Cuvee. Maybe I’ll blend with fruits as well.

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 20 gal | 60 min | 8.7 IBUs | 3.7 SRM | 1.054 | 1.018 | 4.7 % |

| Actuals | 1.046 | 1.01 | 4.7 % | |||

Style Details

| Name | Cat. | OG Range | FG Range | IBU | SRM | Carb | ABV |

|---|---|---|---|---|---|---|---|

| Straight (Unblended) Lambic | 17 D | 1.04 - 1.054 | 1.001 - 1.01 | 0 - 10 | 3 - 7 | 1.8 - 2.6 | 5 - 6.5 % |

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (Weyermann) | 24.306 lbs | 60 |

| Wheat (BestMälz) | 14.583 lbs | 36 |

| Acidulated (Weyermann) | 1.62 lbs | 4 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Northern Brewer | 2.46 oz | 60 min | Boil | Leaf | 3.2 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Phosphoric Acid | 32.40 ml | 60 min | Mash | Water Agent |

| Epsom Salt (MgSO4) | 2.60 g | 60 min | Mash | Water Agent |

| Calcium Chloride | 1.30 g | 60 min | Mash | Water Agent |

| Gypsum (Calcium Sulfate) | 1.30 g | 60 min | Mash | Water Agent |

| Wheat Flour | 5.00 oz | 5 min | Boil | Other |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Bug Country (20) | East Coast Yeast | 70% | 63°F - 75°F |

Mash

| Step | Temperature | Time |

|---|---|---|

| Protein Rest | 122°F | 30 min |

| Saccharification | 156°F | 30 min |

| Mash Out | 168°F | 10 min |

Notes

| After mash-out, drain all liquid into boil kettle, raise temp to 190, pump back to mash for second rinse through grain bed. Pitching ECY20 Bugcountry in 15G barrel, 5G Sparge acidification: Gypsum: 1.9 Grams Epsom Salt: 2.6 Grams Calcium Chloride: 1.3 Grams Phosphoric Acid: 61.9 mL |

Download

| Download this recipe's BeerXML file |