DIY Barrel Transfer tool from Milk the Funk Wiki

After four long years, it’s time to blend and package my first Woxbic beer.

I struggled quite a bit on the blending ratio. Too many variables to take

into account: the volume of beer I could produce to replace what goes into the

blend, the number and size of the barrels I already have, the volume to package,

and ultimately, how the blend would taste.

Transferring Year 1 Woxbic from barrel into a keg

In order to ensure I did have some of year 2 blend left, I needed to limit the

total volume I packaged. The result was that I was going to have quite a bit of

year 3 left over and that I’d need a new barrel to fill for going forward since

I was not also ready to package what would be left in year 3 barrel. Eventually

I settled on a 60/30/10 of Year1/Year2/Year3 ratio, similar to what Jester King

did with their recently released lambic-inspired, Méthode Gueuze beers. I

packaged approximately 10 gallons of blended beer. That works out direclty to 1

gallon of three year old, three gallons of two year and six gallons of one year.

Year 3 and Year 2 barrels transferring into keg for blending.

Year two and year one blends will remain in-barrel (without a top off) for next

year’s blend, and year 3 will have 9 gallons left to package separately. I’m

planning on blending that with some fruits for a cuvee style release as well.

For the actual transfer of the beer, I was excited to use a constructed barrel

transfer tool fashioned after the industry tools, like a Bulldog or

Rack-It-Teer, this was put together by some homebrewers on Milk-the-Funk

community.

The transfers from barrel to keg went flawlessly. A bit of CO2 to push and the

beer flowed quickly into the keg. After collecting all of the volumes, each was

pushed via CO2 into the Chronical where it was recirculated with some bottling

sugar.

Recirculating the blend in the Chronical

Bottling with the Last Straw was nice. The ergonomics of holding the Last Straw

are very nice in comparision to the Blichmann Beergun. I do wish the Last Straw

had a larger diameter for beer. It was designed for already carbonated beer, so

I can understand why the line is small. But for uncarbonated beer, it would be

nice to fill faster.

The weight of the line let the bottle fit itself slowly; that was handy for a single person operation.

With the bottling complete, I now have 6 to 9 months to wait to see how the beer

changes in the bottle. I’ll post some pictures and tasting notes later this

year.

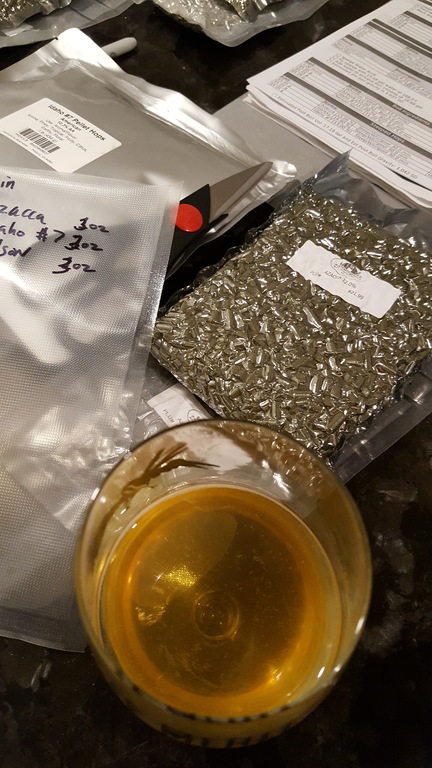

And some fantastic beer to celebrate the occasion.

Dat Crooked Stave!