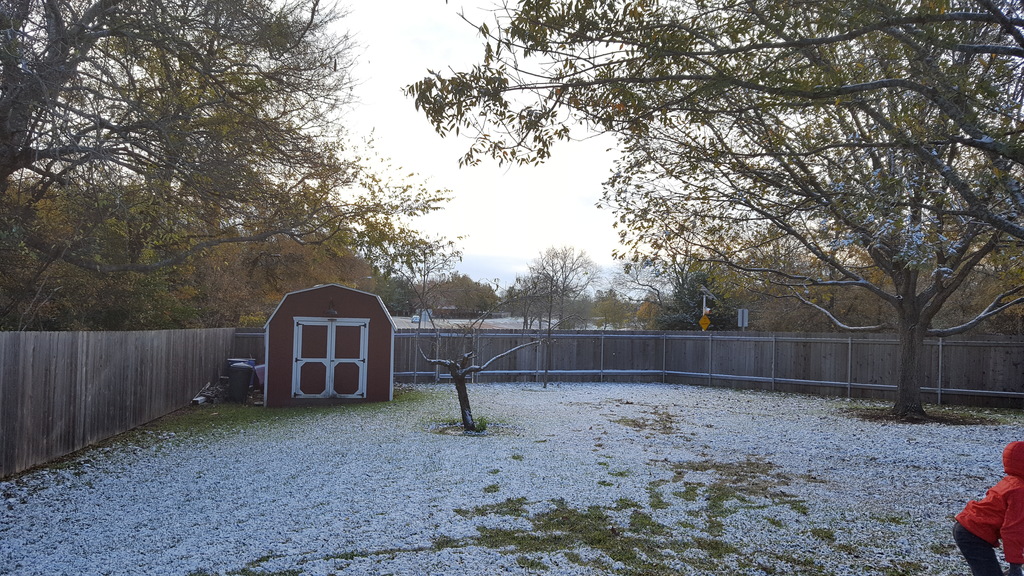

Somewhere between Fall and Winter south Texas actually got some snow! That’s probably the third time in nine years. I know this because my oldest son keeps track of these things. Now that the winter freeze is over and Texas Winter has returned us to the mid 60s F we can resume brewing. The previous NEIPA batch was a huge success in a number of ways so obviously with all three kegs almost gone it’s time to brew another.

The previous batch dropped the gravity down to session levels around 4.6%. I certainly don’t mind or even notice many of the higher ABV NEIPAs in the 6 to 8% range; well that is until I’m two or three pints in and then I’m wishing they were 4% instead so I could have a few more. One challenge with sessions is retaining mouthfeel, however, given the huge amounts of oats and barley in the recipe that isn’t an issue.

The second experimental element in the previous batch was using a mixed-culture yeast that I typically reserve for sour beers. However, it’s a faithful yeast which is known to ferment beers to complete (or nearly there) dryness. I also figured that if the culture did turn a bit sour that wouldn’t be out of place for a NEIPA designed after “juice” anyhow.

Upon the first samples of the beer as it fermented it was quite evident that it was taking a sharp turn down grapefruit lane. That worked out quite well but it did mean that for this recipe the hop bill was going to take a turn toward the more tropical and stone fruits.

Process-wise, no changes. The critical part of brewing stage has been stirring the hops in the filter. The 5-minute charge gets a stir after stopping the heat and then the hop stand gets multiple stirs, every 5 to 10 minutes. While opening the lid means some of the volatile aromas escape the stirring overcomes that loss by extracting more flavors, oils and aroma by saturating the whole batch with the hops.

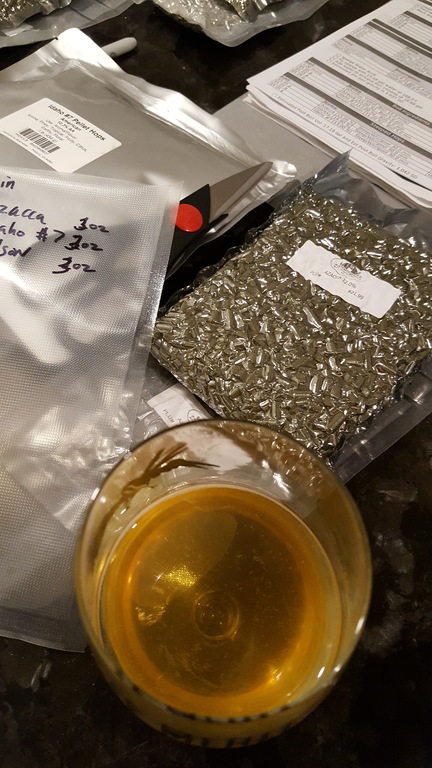

For this batch, I wanted to make use of some aromatic hops that I had around in smaller quantities so I have quite a few more varieties than last time replacing the Meridian and Cascade hops used previously. I also recently had an Idaho #7 hopped beer at Pinthouse Pizza and whole-heartedly approved of those flavors and aromas and chose to have it come along for this NEIPA.

Looking forward to this batch!

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 16 gal | 60 min | 92.8 IBUs | 3.3 SRM | 1.044 | 1.010 | 4.5 % |

| Actuals | 1.044 | 1.01 | 4.4 % | |||

Style Details

| Name | Cat. | OG Range | FG Range | IBU | SRM | Carb | ABV |

|---|---|---|---|---|---|---|---|

| American-Style Pale Ale | 50 | 1.044 - 1.05 | 1.008 - 1.014 | 30 - 50 | 6 - 14 | 2.2 - 2.8 | 4.4 - 5.4 % |

Fermentables

| Name | Amount | % |

|---|---|---|

| Organic Brewers Malt 2-Row (Briess) | 19 lbs | 71.03 |

| Barley, Flaked | 3 lbs | 11.21 |

| Oats, Flaked | 3 lbs | 11.21 |

| Caramel/Crystal Malt - 10L | 1 lbs | 3.74 |

| Cane (Beet) Sugar | 12 oz | 2.8 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Azacca | 3 oz | 5 min | Boil | Pellet | 15 |

| Idaho #7 | 3 oz | 5 min | Boil | Pellet | 13 |

| Nelson Sauvin | 3 oz | 5 min | Boil | Pellet | 11.2 |

| Azacca | 3 oz | 30 min | Aroma | Pellet | 15 |

| Galaxy | 3 oz | 30 min | Aroma | Pellet | 14.8 |

| Idaho #7 | 3 oz | 30 min | Aroma | Pellet | 13 |

| Azacca | 3 oz | 3 days | Dry Hop | Pellet | 15 |

| El Dorado | 3 oz | 3 days | Dry Hop | Pellet | 15 |

| Idaho #7 | 3 oz | 3 days | Dry Hop | Pellet | 13 |

| Azacca | 3 oz | 1 day | Dry Hop | Pellet | 15 |

| Ekuanot - Equinox (HBC 366) | 3 oz | 1 day | Dry Hop | Pellet | 15 |

| Idaho #7 | 3 oz | 1 day | Dry Hop | Pellet | 13 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Phosphoric Acid 10% | 61.90 ml | 60 min | Mash | Water Agent |

| Calcium Chloride | 5.80 g | 60 min | Mash | Water Agent |

| Epsom Salt (MgSO4) | 1.50 g | 60 min | Mash | Water Agent |

| Gypsum (Calcium Sulfate) | 1.50 g | 60 min | Mash | Water Agent |

| Whirlfloc Tablet | 3.00 Items | 15 min | Boil | Fining |

| Yeast Nutrient | 3.00 tsp | 3 days | Primary | Other |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| London Ale III (1318) | Wyeast Labs | 73% | 64°F - 74°F |

Mash

| Step | Temperature | Time |

|---|---|---|

| Saccharification | 152°F | 60 min |

| Mash Out | 168°F | 10 min |

Notes

| Nor'easter V2 - Really need the rice hulls with all of the rolled oats and barley - Giving London Ale III yeast a try. Not sure about the sugar addtion or not. I really do want a dry beer; so we'll see how gravity drops and if it gets sluggish around 1.020 , I'll likely add some to keep the fermentation going and drop the final gravity. - Stirring the hop additions *really* makes a huge difference. |

Download

| Download this recipe's BeerXML file |