Filled the barrel with boiling water to prepare the barrel for aging

I’ve been working on sour beers for nearly a year and I’ve only now decided to attempt a Lambic-style beer. I always wanted to use a barrel for aging lambic-style beer but the size that’s available to a homebrewer isn’t practical for long term aging due to high oxygen to volume ratio; something that can spoil this multi-year process. Over this past year I’ve read a number of attempts and various processes employed by crafty homebrewers to minimize oxygen permeability. Plus, my largest barrel (11 gallons) has finally given up the whiskey ghost, so it’s time to make it the home of some sour bugs. A few more things forced my hand. In December, I was able to pick up the coveted ECY 20, Bug Country blend of yeast and bacteria. The list of microbes included is simply stunning.

- Brettanomyces lambicus

- Brettanomyces bruxellensis

- Brettanomyces anomulus

- Brettanomyces clausenii

- Brettanomyces custersianus

- Brettanomyces nanus

- Brettanomyces naardenensis

- Various Lactobacilli and Pediococci

- ECY01 BugFarm

- ECY02 Flemish Ale

- ECY03 Farmhouse Brett

- ECY04 Brett Blend #1

- ECY05 Brett Blend #9

You can read more about the strains included at East Coast Yeast.

With such a great yeast blend, I needed to brew a beer that would handle such a blend. Empty barrel, great yeast. Lambic-style? Yeah!

Keeping a beer around a long time is challenging. Most of my aged sours are in PET or glass carboys; a few in a stainless corny keg. I agree that lambic-style beers need contact with wood to obtain a good flavor profile, but smaller barrels are going to introduce too much oxygen over a year or more. Over at the Funk Factory, a post about using paraffin wax to seal the barrel caught my eye. In addition to the waxing, a home-made steam wand was also something I needed to make so I could ensure that the bugs in ECY20 take over the barrel, not something else that might be in there.

Hot water cleaning a freshly dumped barrel

I’ll be following up this post with a few more on both barrel steaming and barrel waxing.

For the recipe, I’m following the traditional 60% barley (pils) and 40% wheat. I’m not performing a turbid mash so I’m attempting to come close to emulating the result which is to have a wort with lots of unconverted starch. The unconverted starches become food for the various microbes over the long haul. Sacchromyces yeast won’t eat those starches, but both Brett and the bacteria (Lacto, Pedio) will. I’m using torrified wheat so I don’t have to do a cereal mash to soften them up. And just to ensure we have some starch, I’m also throwing in some wheat flour. Various homebrewers have had success, but no rule of thumb on the amount, so this is just a guess. We’ll see how well it works.

Another important aspect to lambic-style beer is locality of ingredients. I had planned on getting some wheat and pilsner from our new local micro malster, Blackland Malting up in Ceder Park, but their release in December was picked up by the local scene and they’re completely sold out of what they had. Pils and Wheat won’t make it out again till this summer. Look for v2 of Woxbic to include these malts. Normally I use Reverse Osmosis water to pull all of the elements and nasties out of the water and build a new profile with salts. Instead, I’ll use my local water. This has it’s own challenges since the city water is heavily bicarbonate as well as having lots of chloromines. To combat this, I’m employing a whole-house carbon filter, campden tabs, and lots of phosphoric acid so I can have a low residual alkalinity for mashing with light grains. I’ll follow up with a post on the water process used as well.

Here’s the recipe for Woxbic, the first lambic-style beer I’m attempting.

Recipe Details

| Batch Size |

Boil Time |

IBU |

SRM |

Est. OG |

Est. FG |

ABV |

| 12 gal |

90 min |

8.9 IBUs |

3.8 SRM |

1.051 |

1.012 |

5.0 % |

|

Actuals |

1.046 |

1.01 |

4.7 % |

Style Details

| Name |

Cat. |

OG Range |

FG Range |

IBU |

SRM |

Carb |

ABV |

| Straight (Unblended) Lambic |

17 D |

1.04 - 1.054 |

1.001 - 1.01 |

0 - 10 |

3 - 7 |

1.8 - 2.6 |

5 - 6.5 % |

Fermentables

| Name |

Amount |

% |

| Pilsner (2 Row) Bel |

16 lbs |

61.54 |

| Wheat, Torrified |

9 lbs |

34.62 |

| Acidulated (Weyermann) |

1 lbs |

3.85 |

Hops

| Name |

Amount |

Time |

Use |

Form |

Alpha % |

| Crystal |

1.5 oz |

60 min |

Boil |

Pellet |

3 |

Miscs

| Name |

Amount |

Time |

Use |

Type |

| Wheat Flour |

3.00 oz |

5 min |

Boil |

Other |

Yeast

| Name |

Lab |

Attenuation |

Temperature |

| Bug Country (20) |

East Coast Yeast |

70% |

63°F - 75°F |

Mash

| Step |

Temperature |

Time |

| Acid Rest |

93°F |

15 min |

| Protein Rest |

113°F |

15 min |

| Saccharification 1 |

131°F |

15 min |

| Saccharification 2 |

149°F |

15 min |

| Mash Out |

168°F |

10 min |

Notes

After mash-out, drain all liquid into boil kettle, raise temp to 190, pump back to mash for second rinse through grain bed.

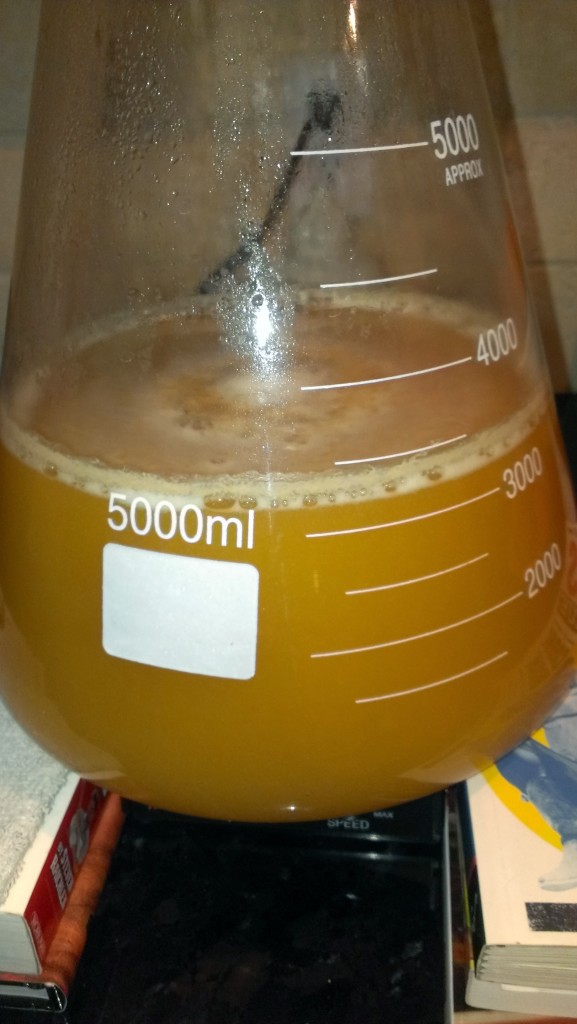

Pitching ECY20 Bugcountry in 11G barrel. |