One of my friends asked me to come down for a bottling day at Jester King Brewery in Austin, Texas this past week. He’s been a few times and knew the ropes and all of the hard work the volunteers put in to help out a favorite local brewery. I’m a huge fan of Jester King, the beers they make and the hand-crafted nature of their approach to making beer. This appreciation provided a huge boost of enthusiasm to help cope with the over 100F degree temperature encountered during the 8+ hour work day.

With the help of probably 10 or so volunteers and some brewery employees we packaged 200+ cases of Funk Metal, a barrel-aged sour stout beer. Funk Metal has a special place in my cellar; it has displayed New Belgium’s La Folie as my favorite sour beer that I’ve tasted.

The work day began with assembling all of those boxes with inserts, followed by marking the boxes and placing inventory labels on each box in the 5-high stacks. We watched as the brewers readied the beer for bottling by recirculating the beer in the tank with sugar and healty pitch of Brett. Drie yeast for bottle conditioning. The light smell of tart, lactic, sour beer flooded the air, along with all of the crazy awesome Funk music blasting out the brewery speakers.

176 bottles per layer, 14 rows of 7 and 13 rows of 6. 7 layers per pallet combine to make over 1200 bottles. Yeah, lots of bottles.

Close to noon, the bottling line was taking form. I was placed at the bottle prep station where we unpacked pallets of belgian brown glass bottles, over 1200 per pallet. Each bottle was placed into a cleaning station where sanitizer was used to prepare the bottle for filling. As the filler pulled from the rack, we replaced a new bottle and then opened the valve to clean another set of bottles. This line ran continuously for 6 hours. As we used the bottles, we opened up the next layer (7 layers total) and eventually replaced the pallet with another one.

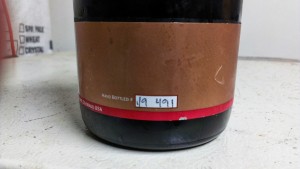

After the bottles were filled, the next station used a co2-driven capper and passed the bottle to a group wiping the bottles down and checking the fill level. Once the bottles dried a bit, the label station applied the amazing artwork labels Jester King beers are known for and the UPC and batch label. All of the bottles were then boxed and stacked on a pallet. Full pallets were moved back into cold storage for conditioning for a few months before being released into the market.

One of the great perks of working at the brewery is sampling of the great beer. All throughout the day the team sampled a few of the beers on tap. My favorite for the day was the Salt Lick smoked saison which is a blend of a young saison with some old aged sour beer yielding a very smooth, slightly smokey but tart, crisp finishing beer. It was a huge thirst quencher.

When we weren’t sampling the great beer at Jester King we were drinking some flavorful bottled rainwater. It’s amazing how much better that water tasted than the normally sterile store bottled water.

Heading home in the evening I was exhausted, hot, sweating, tired, but laden with beer-sweat-equity; some bottles of Funk Metal that didn’t make the cut.

At the end of the day, my friend asked me if it was worth all of the hard work, and all I could say was that even without the beer I would definitely do it again.

Thanks Jester King!